As users demand for better consumer electronic products, every brand company continually improves the technical aspects and appearances of its products. In the last two years, some global leaders already launched portable electronic products with mini-LED backlight. In light of this emerging trend, Macroblock, the mini-LED backlight driver IC leader, has also assisted our clients to speed up the adoption of MBI6322 and MBI6334 for compact, stylish and high picture quality portable electronic products.

Nowadays consumers not only care about the display performance of portable electronic products but also focus on the size and looks of them. Macroblock’s MBI6322 and MBI6334 are equipped with “high-scan type”, “highly-integrated feature” and “S-PWM technology & black frame insertion function” that can be adopted for the making of brilliant products and accelerate the market penetration rate of mini-LED backlight related products. Please refer to the following:

- 1. High-scan type to realize compact design

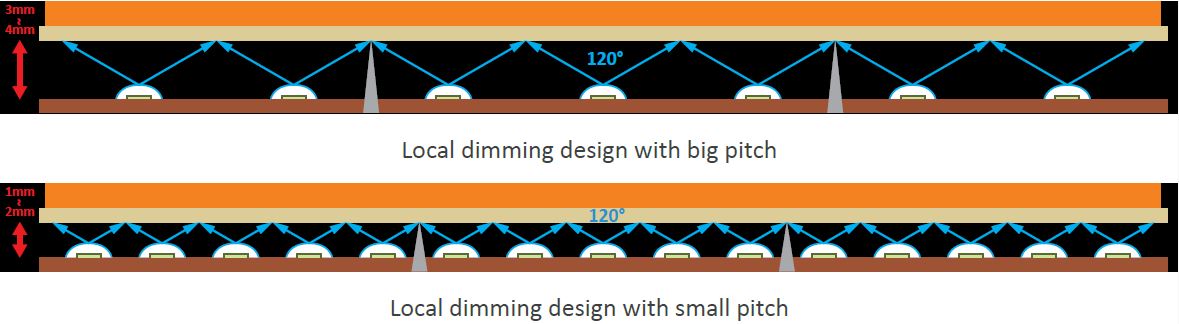

- Through small pitch local dimming backlight design, portable electronic products can reduce the optical distance (or even achieve "Zero" OD) so as to make products more compact.

The optical distance of LED backlight design introduction

- But small pitch local dimming backlight design applies more mini-LEDs, which means more LED driver ICs will be used. Given the limited backplane space, growing component counts contradict the spirit of compact design. In order to overcome the issue, Macroblock mini-LED backlight driver ICs supporting high-scan type, compared to general solutions, enable designers to control more zones with fewer driver ICs to realize the real compact design.

- 2. Highly integrated feature to create stylish product

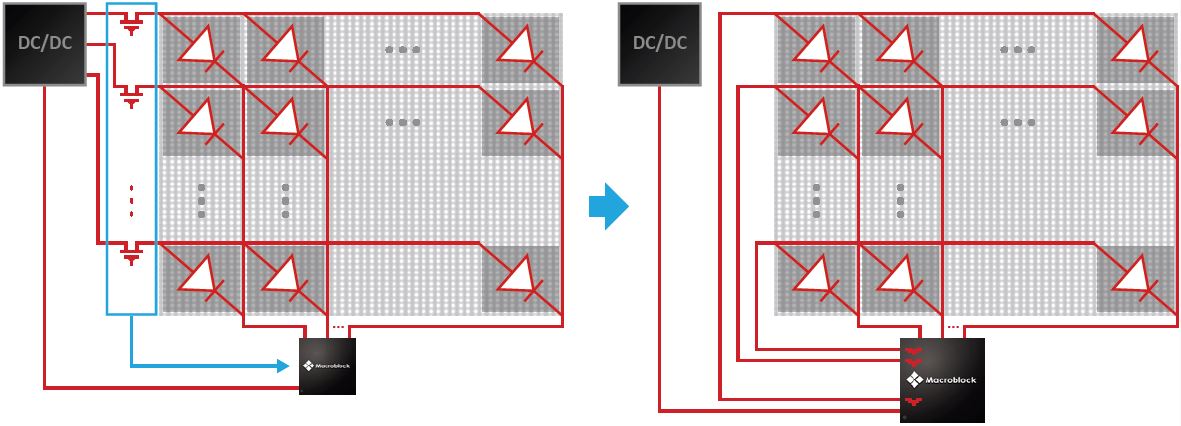

- Portable electronic products are seen as fashion accessories by consumers recently. Therefore, brands need a flexible PCB layout in their design to create modern and stylish products. Macroblock offers mini-LED backlight driver ICs that are highly integrated by incorporating the MOSFET switch into the LED driver IC (as below picture). The design streamlines the PCB layout of the driver board and frees the product industrial design from many limitations. This assists brands to create products meet customers' expectation.

Backlight design with highly-integrated Macroblock's driver IC

- 3. S-PWM technology & black frame insertion function to perform high picture quality

- a. S-PWM technology solves flickering issue

- Portable electronic products control backlight brightness with pulse-width modulation (PWM). This technology adjusts brightness by turning on and off the light source, therefore causing the image to flicker. Traditionally, the issue is addressed by increasing the PWM frequency; however, this method can cause picture quality to be compromised if the grayscale clock is not fast enough to match the high grayscale. But Macroblock’s backlight driver ICs use S-PWM to effectively boost grayscale clock frequency in an effort to solve the flickering issue.

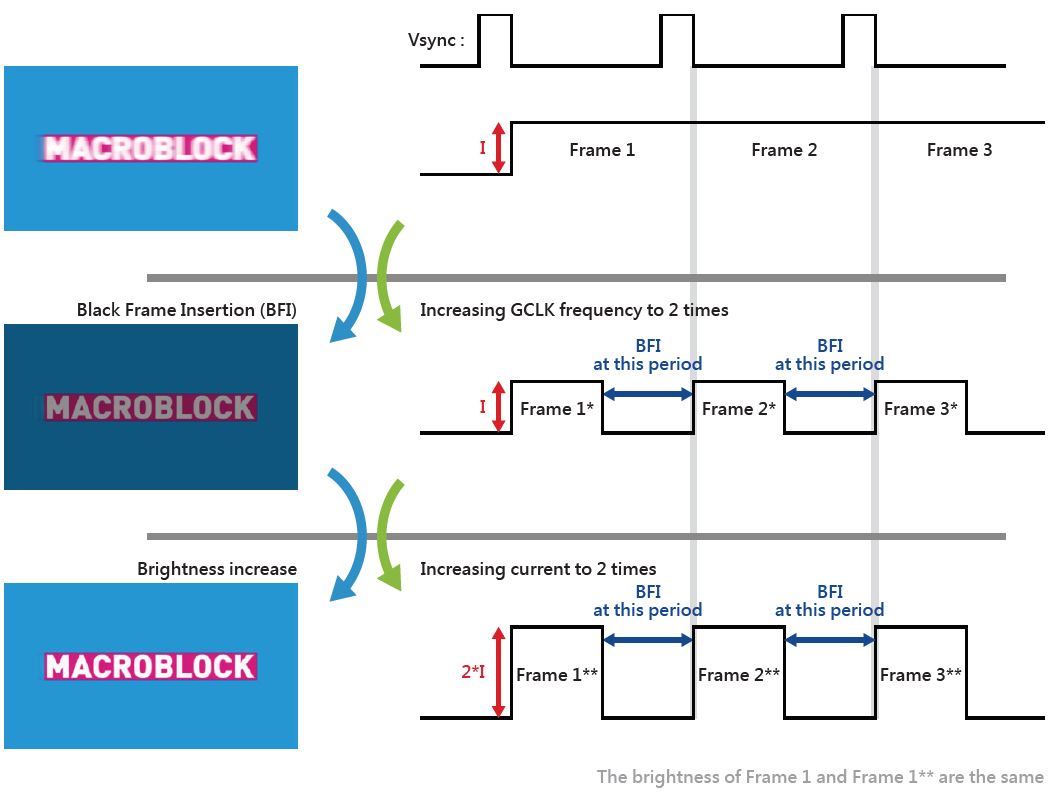

- b. Black frame insertion function solves motion blur issue

- As grayscale voltage or gamma voltage twist LCDs, it takes some time for the LCDs to twist liquid crystals to the correct grayscale. Since the backlight remains on, the picture blurs while the light passed through the twisting liquid crystals. The solution to the motion blur problem related to the timing controller. The timing controller doubles the frame rate by inserting black even- or odd-numbered frames. The method requires a timing controller to possess additional digital signal processing components and double data rate, which means the chip will be bigger and much more costly. To overcome motion blur, Macroblock proposed the black frame insertion function. The picture below shows how the function boosts grayscale clock frequency so that it finishes sending the frame data early, leaving enough time for black frame insertion to minimize the motion blur issue.

Black frame insertion introduction