The packaging technology of LED display modules can be divided into two types, one is SMD (Surface Mounted Devices) and the other one is COB (Chip On Board). For the indoor fine-pitch full-color LED display applications, the main SMD product is the 4in1 LED module, and the main COB product is the flip-chip COB module. The comparisons of these two products are as follows:

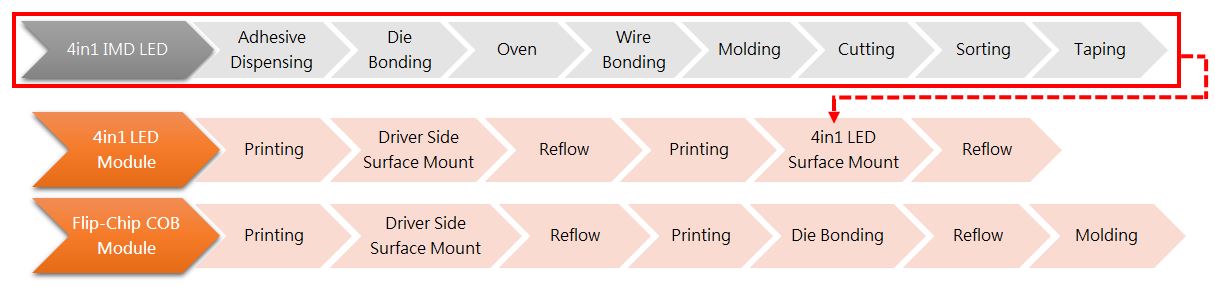

- I. Production Cost: As compared to the flip-chip COB module, the 4in1 LED module has more production workstations (as shown in the picture below), which increases production cost. In addition, the flip-chip COB module adopts the mass transfer method to set LEDs on PCB boards; however, the 4in1 LED module applies traditional single-chip per transfer method to set LEDs on PCB board one-by-one. Thus, the production capacity is ten to hundred times different. The cost advantage of flip-chip COB module may help speeding up the construction and expansion of virtual production environments.

- II. Display Performance: The flip-chip COB module adopts the mass transfer method, and LEDs are precisely placed on PCB boards so that the flatness and accuracy of the module are outstanding. After that, the whole set will be molded to create a uniform and neat LED surface. The 4in1 LED module applies single-chip per transfer method; therefore, LED surface might appear a color cast with 4 pixels as a unit (because the four pixels are combined in a package). Moreover, the viewing angle of the flip-chip COB module is around 175°, which is wider than the 160° viewing angle of the 4in1 LED module, and there is no pixel granularity on the flip-chip COB module. In addition, the flip-chip COB module can effectively suppress the moiré effect, and greatly improve the visual effect and filming flexibility of virtual production.

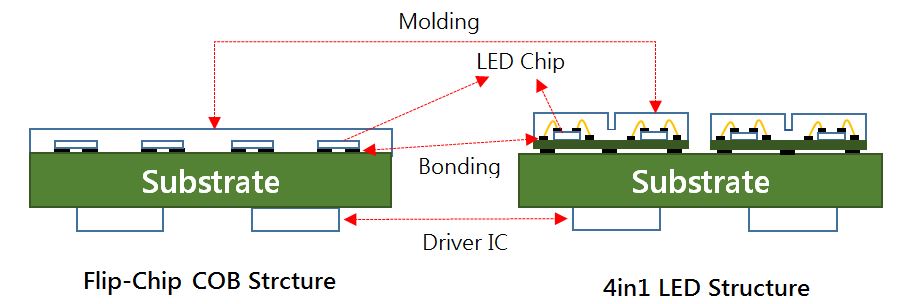

- III. Product Reliability: Picture 2 shows the lateral structure of a flip-chip COB module and a 4in1 LED module. The LED surface of the flip-chip COB module is packaged with an integral epoxy resin mold to avoid oxidation; the exposed solder joints of the 4in1 LED module are susceptible to interference by water and oxygen.

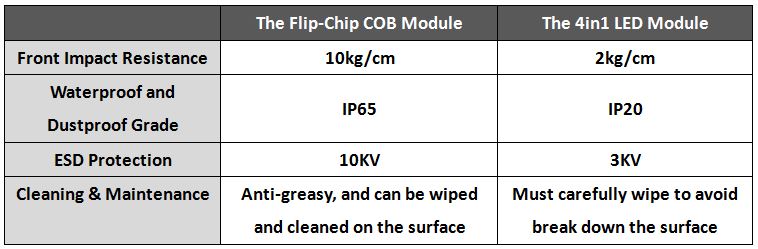

- Please refer to the following comparison table of product reliability. Comparing the various characteristics, the overall reliability of the flip-chip COB module is much better. It is more suitable for the film and TV industry that requires frequent disassembly and assembly of LED modules.

In summary, from the perspective of production cost, display performance and product reliability, the flip-chip COB module is significantly better than the 4in1 LED module. Macroblock is glad to see the continuous development of the flip-chip COB module technology, which propels LED display industry to achieve sustainable growth, provides buyers with high-quality products and brings viewers an excellent visual experience.